How to choose Ultrasonic Cleaner

How to Choose

In addition to ultrasonic cleaning, industrial cleaning includes jet-flow cleaning, bubbling cleaning, shower cleaning, cleaning while moving up and down, and vapor cleaning. Each cleaning method differs depending on the contamination of the workpiece and the required cleaning quality.

Ultrasonic cleaning has the following features

・Uniform cleaning quality

・Shorter cleaning time

・The entire workpiece can be cleaned (advantageous for precision parts and parts with complex shapes).

How to select a model of ultrasonic cleaner

In ultrasonic cleaning, it is important to select an appropriate cleaning solution according to the type of contamination and to combine the physical action of ultrasonic waves with the chemical action of the cleaning solution to maximize the cleaning effect.

(1) Purpose of cleaning: degreasing, removal of polishing powder (buffing powder), chips, particles, etc.

(2) Type of workpiece (workpiece to be cleaned): material, dimensions (if a basket is used, dimensions of the basket), etc.

(3) Selecting the type: separate type (generator and transducer are separated),benchtop type, quartz transducer unit type, and nozzle type.

*When introducing an ultrasonic cleaner, it is also important to determine which processes will be incorporated into the system.

At least three processes are required: washing, rinsing, and drying.

Frequency Selection to Objects to be Cleaned

| Stain Size | Example of dirt application to be cleaned | Damage to workpiece | Frequency | Special feature |

| Visible stains | Oil-based Degreasing and cleaning of metal parts Degreasing and cleaning of resin Removal of polishing powder (buffing powder) and chips |

Big

|

28kHz | Used to remove persistent contamination such as grease, due to the strong cleaning energy. Enhances the effectiveness of the cleaning liquid. |

| 10 μm or more | Dust Initial cleaning of LCD glass, Cleaning of precision metal parts |

40kHz | It is often used to clean precision parts because it causes less damage to the workpiece than 28 kHz. | |

| 5μm~10μm | Cleaning of HDD, CSP substrates, precision metal parts, optical disks and HD heads | 75kHz ~ 100kHz |

It is often used when 40 kHz causes damage to the workpiece. This frequency has been attracting attention recently because it has relatively strong cleaning energy and causes less damage to the workpiece. | |

| 1μm~10μm | Compound Wafer HDD |

120kHz ~ 160kHz |

Used to perform initial cleaning of wafers. Possible to remove fine contamination with minimal damage to the workpiece. |

|

| 0.2μm~5μm | Silicon Wafers Glass wafers and glass substrates |

400kHz | A wide range of particle sizes to removeand various precision cleaning are expected. | |

| 0.2μm~1μm | Final cleaning of glass substrates, silicon wafers (with circuits), glass masks | 1MHz | Used to remove small particles that are not visible to the naked eye. Less damage to the workpiece. Widely preferred as the frequency to use for wafer cleaning. |

|

| 0.2μm or less | Silicon wafer (with circuit), glass mask | 3MHz | Used for the finer particle removal than cleaning by 1MHz. |

Type Selection

Separate type

Separate type ultrasonic cleaners consist of a generator and transducer unit. Various

combinations can be selected to suit the application, facility, and purpose

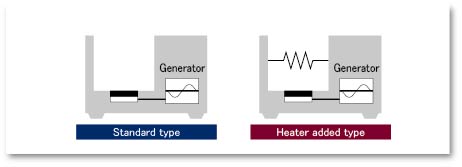

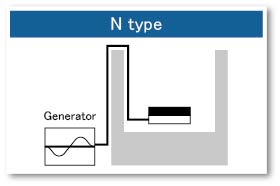

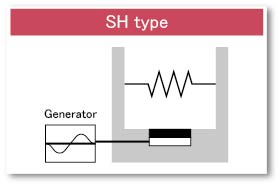

Combination of generator and immersible type transducer unit.

Can be used with your own cleaning tank.

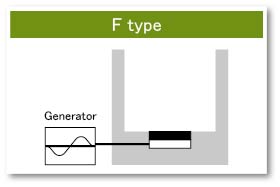

Combination of generator and vibration plate (flange) type transducer unit.

Can be used for incorporation into equipment, etc.

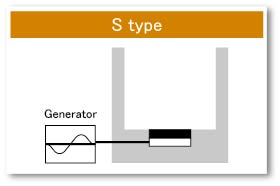

This is a combination of an generator and a dedicated cleaning tank.

Easy to install and ready to use.

S type cleaner with heater. The effects of

warm water achieve stronger cleaning

power.

Quartz transducer unit type Type

Ultrasonic waves are superimposed on quartz transducer unit to clean semiconductor wafers.

For product information on quartz transducer unit type ultrasonic cleaners, please visit Semiconductor Industry.

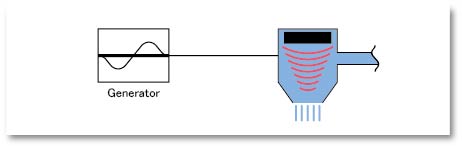

Nozzle type

This type cleans by placing high-frequency ultrasonic waves in a stream of water.

For product information on Nozzle type ultrasonic cleaners, please visit Semiconductor Industry.

See Ultrasonic Cleaners for product information on all ultrasonic cleaners.

If you need help selecting a product, please contact us.

Our experienced representatives will carefully advise you on product selection. We can also guide you to our distributors.

We can also perform cleaning tests in our lab room at our headquarters. Please use this inquiry form to contact us.

Cleaning tests are available at any time in our lab room at our headquarters.

Please contact us for details.