Informative applications of ultrasound

The signals emitted from ultrasonic sensors are used for informational applications by propagating them through a medium (gas, liquid, or solid). Typical applications include level meters, flow meters, non-destructive testing equipment, and fish finders.

Ultrasonic Features

Slower velocity of propagation than radio waves and light, enabling more accurate measurements.

Advantageous for measurements in liquids and solids, where light transmission is poor, and for distance measurements to transparent objects that do not reflect lightShorter wavelength and more directional than audible sound

Propagation attenuation is greater than that of audible sound, making it difficult to reach far away.

Products

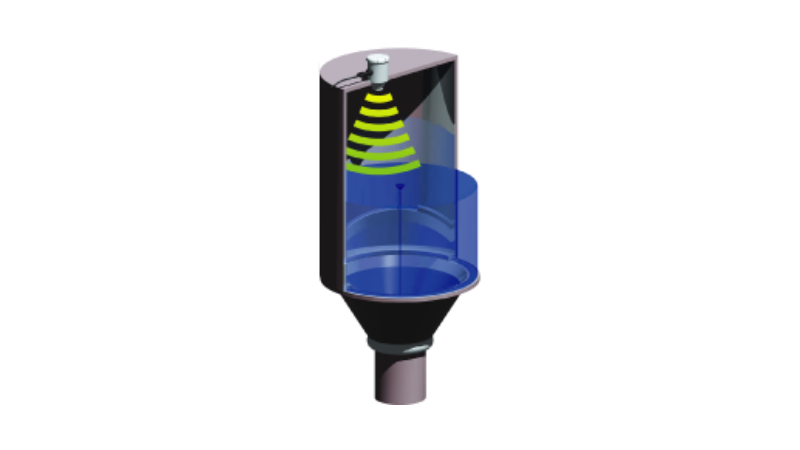

level meter

Also called liquid level gauge, liquid level gauge, or water level gauge.

By measuring the time it takes for ultrasonic waves emitted from the sensor to be reflected by the object to be measured and the time it takes to receive the reflected waves, the liquid level in a tank can be measured and the remaining amount of raw material can be managed.

Since the sensor continuously measures without contact with the object to be measured, it requires less maintenance and reduces labor costs. Using the signal output from the level meter, the flow of liquid into and out of the tank can be controlled using a pump.

A weir flowmeter function is also included in the standard specifications, allowing management of flow rates through triangular weirs, square weirs, and partial flumes.

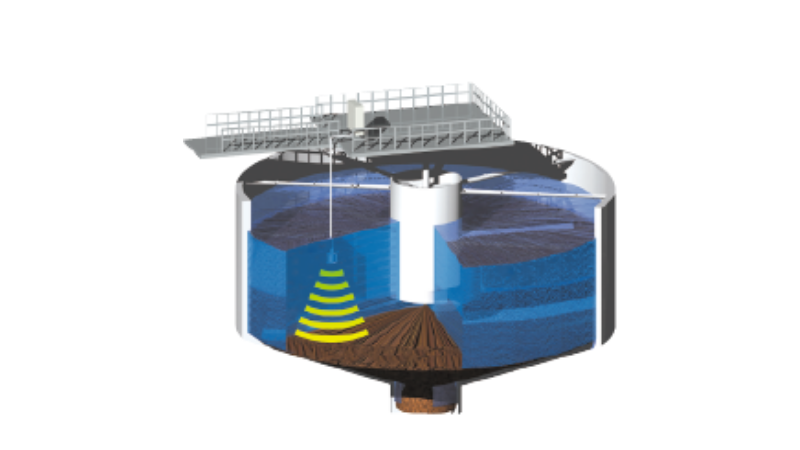

Interface Level Meter

Also called sludge interface meter.

Ultrasonic waves have the property of reflecting at the interface between different media. Ultrasonic waves are transmitted from a sensor installed in the water, reflected at the interface, and the height of the interface is calculated from the time it takes to receive the reflected waves.

Since the measurement is non-contact with sediments such as sludge, it is possible to measure without disturbing the sludge interface that has formed. It is also possible to measure the interface level in opaque treated water where light penetration is poor.

The operation of the mud pump can be controlled using the measured data from the interface level meter. It is also possible to check the degree of sludge settling, which is useful for timing the feeding of coagulant (PAC).

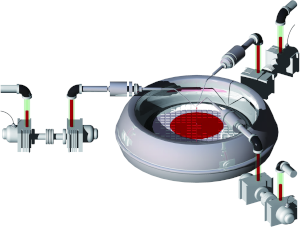

Flow meter

Sensors are installed upstream and downstream of the flow, each sensor transmits ultrasonic waves in the forward and reverse directions, and the velocity is determined from the difference in propagation time of the ultrasonic waves and converted to flow rate. Since ultrasonic flowmeters have no structures in the piping, they can measure flow rates under conditions of minimal pressure loss. It can also measure a wide range of flow rates from small to large.