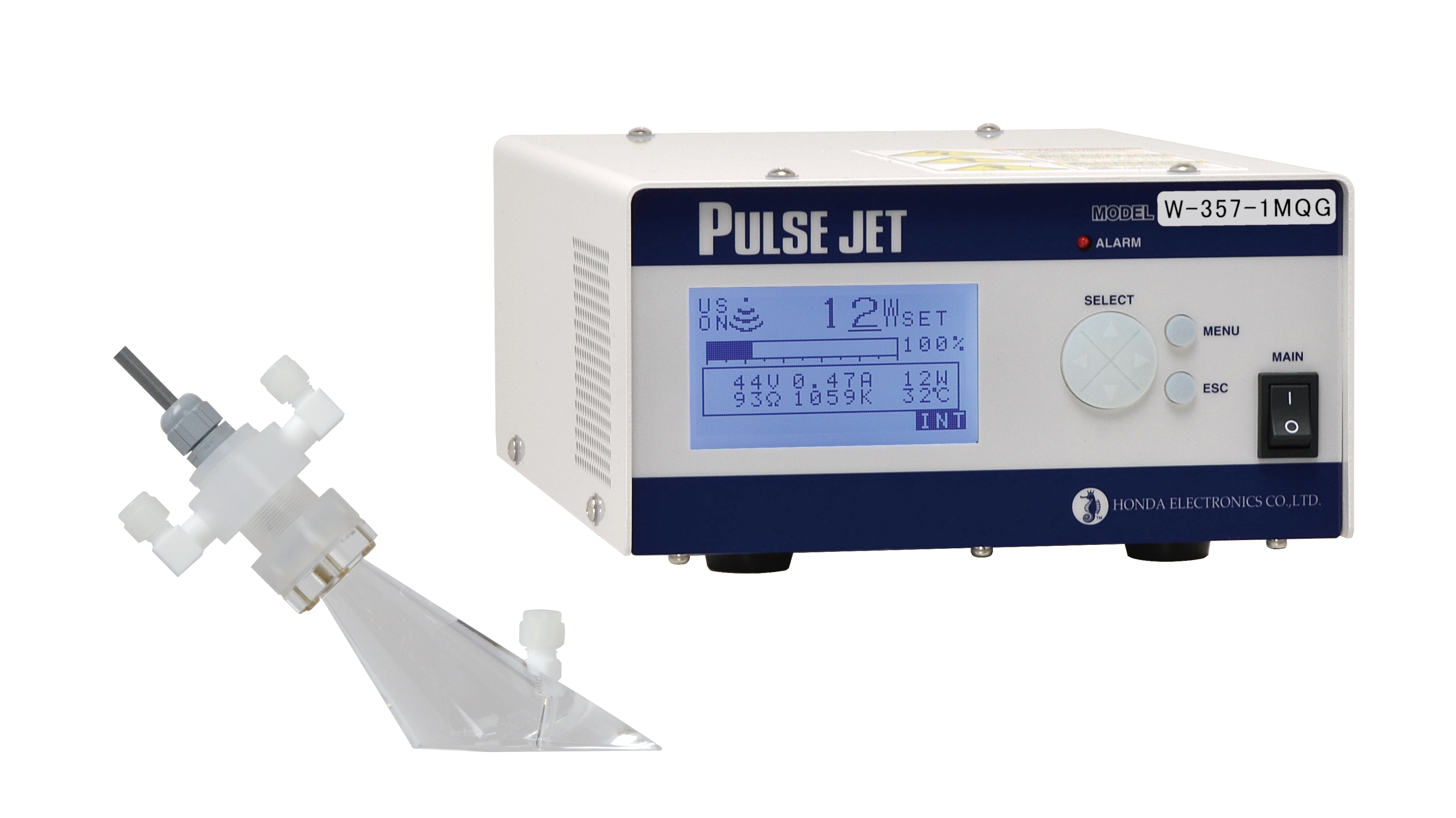

Quartz Transducer Unit Type Cleaner [High Frequency] |W-357-1MQG-SKC

Quartz Transducer Unit Type

Next-generation cleaning for low damage and high cleanliness

In 2006, we became the first company in the world to commercialize a quartz transducer ultrasonic cleaning unit.

In this method, semiconductor wafers are cleaned by superimposing ultrasonic waves on a quartz transducer.

Compared to batch and nozzle type cleaning, the amount of chemicals used can be reduced, and since only quartz glass is in contact with liquid and no rubber materials such as packing are in contact with liquid, a high level of cleanliness can be maintained.

In addition, the quartz transducer is available in various shapes to meet different cleaning needs, such as low-damage cleaning, large-area cleaning, and cleaning of bevels (edge surfaces) and notches (notches on the wafer edge surfaces).

Overview

Special feature

Cleans fine-patterned wafers with minimal damage

■Cleaning semiconductor wafers by superimposing ultrasonic waves on a quartz transducer unit

By propagating ultrasonic vibration from the quartz transducer unit to the semiconductor wafer through the chemical solution, the chemical solution in contact with the wafer vibrates, and the acceleration of the vibration removes contaminants from the surface.

■Clean cleaning is achieved with minimal damage to the semiconductor wafer.

By using quartz for the chemical contact area, there is no elution or abrasion of rubber compared to equipment using rubber materials such as packing, and clean cleaning is realized.

■The transducer cooling function enables stable continuous operation without frequency fluctuation by cooling the transducer with gas (nitrogen, etc.).

Cooling also eliminates abrupt temperature changes and extends service life.

Applications

Resist residue removal

Polymer removal after edging and ashing

Gate electrode cleaning

Cleaning after CMP

Specifications

■Generator

| Model | W-357-1MQG-SKC |

| Oscillation mode | Single Frequency Oscillation |

| Rated output | 12W |

| Nominal oscillation frequency | 1MHz |

| Power input | AC100V~240V Single phase 50/60Hz 300VA |

| External Dimensions WxDxHmm |

180×250×100 (Excluding protruding parts, including rubber feet) |

| Weight | 2.2kg |

●Variable output range: 0W to 12W (Allowable input of the transducer: 10W continuously when air purge is used to cool the transducer)

●Ambient operating environment: Temperature: 15 to 35°C, humidity: 10 to 85%.

●External drive contact rating: Ultrasonic oscillation control (control side) contact input: 12VDC 16mA or more

Output for alarm (main unit) contact capacity: 24VDC 0.5A

■Attached cable: Power cable (2m for 100V/3m for 200V), control cord (5m) x4

■Transducer Unit

| Flow rate | No designation |

| Over-all length | 159mm |

| Chuck dimensions | φ24mm |

| Cleaning area | 24cm2 |

| Weight | 600g |

●Liquid temperature range: 20 to 50°C

●Transducer: PZT

●Material: Transducer Unit: Quartz glass, Packing: Silicone rubber, Case: PCTFE

●Cable length: output cable 1.5m + relay cable 3.5m

●Air purge fitting: Compatible tube (outer diameter φ6)

*2MHz, 3MHz, 4MHz, or 5MHz are available.