HL2L00 [Ultrasonic Interface Level Meter]

Overview

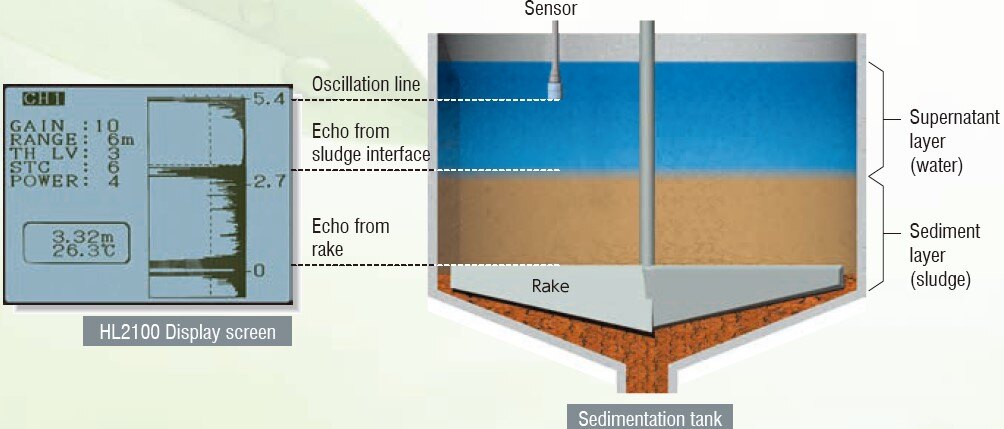

Sedimentation state is calculated from the time it takes for ultrasonic waves to reflect at the interface and be received.

Ultrasonic waves have the property of reflecting at the interface between different media.

Sedimentation state is calculated from the time it takes for ultrasonic waves to be transmitted from the sensor in the water, reflected at the interface, and received.

Since the measurement is non-contact to the sediment, it is possible to measure the interface of opaque treated water or the interface in deep tanks without lowering the sensor to the target sediment.

Since the measurement is non-contact to the sediment, it is possible to measure the interface of opaque treated water or the interface in deep tanks without lowering the sensor to the target sediment.

Special feature

・A wide range of distances can be measured from 0.2 to 10 m from the sensor's transmitting surface.

・Two sensors can be connected to the unit at the same time, so interface measurements can be performed at two locations (Another sensor is required separately )

・Using ultrasonic waves enables measurement without effects from transparency, chromaticity and regardless of day and night.

・The interface is measured by processing calculations based on the assumption of changes in the quality of the upper water and sediment sludge concentration, so there is no need to change the setting values or readjust them depending on the condition of the facility.

・No driving parts in the converter and sensor, which enables stable measurement over a long period of time.

・RS-485 communication function

As ORIGINAL communication, it can be monitored with management software (LV Monitor2)

In MODBUS communication, it can be controlled and monitored by remote access.

Management software (LV Monitor2)

Output

・Alarm output

・4-20mA

Applications

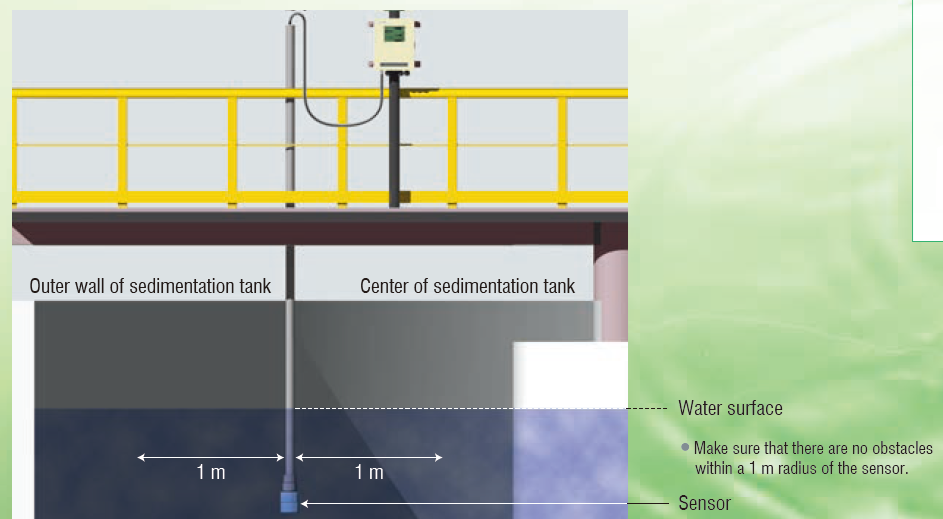

・Interface level control in sedimentation tanks at water treatment plants, sewage treatment plants, and industrial wastewater treatment facilities

Application Example

Specifications

| Model | HL2100 | |

| Number of Channels | 2CH | |

| Frequency | 400kHz | |

| Object of measurement | Sludge interface | |

| Distance measurement range | 0.2~10m | |

| Resolution | Measure | 1cm |

| Display | 1cm | |

| Data updating cycle | 1 second | |

| Sensor directivity angle (sound pressure half full angle) | 6° | |

| Power | Voltage | 100V-240V AC 50/60Hz |

| Power consumption | 18VA | |

| Display | LCD display (with backlight) | |

| Output | Alarm output | 2 points each for upper and lower CH 250V AC, 30V DC, 1A (relay contact) |

| 4-20mA current output | Resolution: 16bits, 1 point per CH (Maximum load resistance 450Ω) |

|

| Interface |

RS-485 1point |

|

| Model |

Main unit |

Sensor |

| Ambient operating temperature | -10~60℃ | -5~60℃ |

| Material | Steel coating | Case: PVC Cable: PVC |

| Structure |

IP54 Equivalent *1 |

IP68 Equivalent |

| External dimensions (WxDxHmm) | 280x96x352 | φ80x95 |

| Sensor cable length | - | 20m |

| Maximum allowable sensor cable length | - | 100m*2 |

| Weight | 5.4kg | 1.9kg |

* 1 Use a cable with an outer diameter of φ6.5 to 9 mm. Put a sealing plug and a waterproof hole plug together as attached package.

* 2 Contact us if sensor cable extension is required.

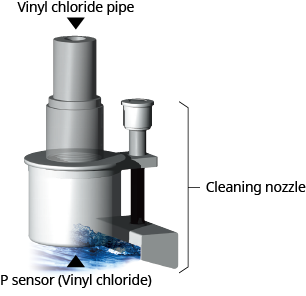

Sensor cleaning method

Dirt on the sensor surface can interfere with sludge interface measurement, so please keep the sensor surface clean at all times.

Periodic wiping or constant cleaning with the optional cleaning nozzle is recommended.

When using the cleaning nozzle, always run water.