HD323 [Ultrasonic Level Meter]

Overview

Special feature

● The 2-wire system reduces installation, wiring, and operating costs.

What is 2-wire system?

The 2-wire system is a signal transmission method that eliminates power supply wiring by obtaining power for the amplifier from the current output signal.

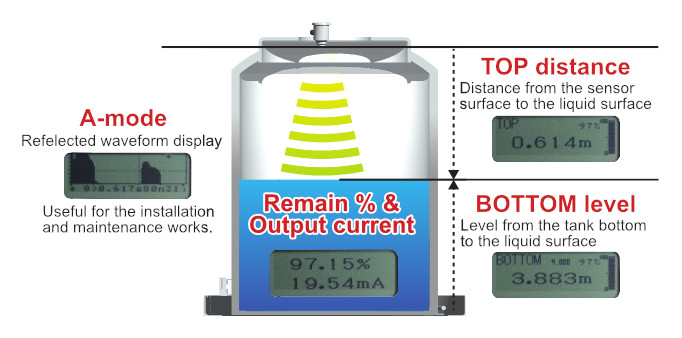

● Four display screens by switching

The main unit display can be switched between four different display screens.

● Mask processing

Manual mask processing is available.

Mask processing can be applied to obstacles within the sensor directivity angle for measurement.

Applications

Liquid level control of tanks, etc.

Level control of treated water in sewage pipes

Water level measurement of lakes, swamps, and rivers

Specifications

| Model | HD323 | |

| Number of Channels | 1CH | |

| Frequency | 50kHz | |

| Object of measurement | liquid | |

| Distance measurement range | 0.25~7.5m | |

| Resolution | Measurement | 1mm |

| Display | 1mm | |

| Accuracy | ±0.25%F.S. (±18.8mm) |

|

| Data updating cycle | 10 seconds | |

| Sensor Directivity Angle | 14°(-6dB) / 10°(-3dB) | |

| Power | Voltage | DC24V |

| Power consumption | 0.6W | |

| Display | Graphic LCD | |

| Display size | LCD 50x25mm | |

| Output | 4-20mA current output | Resolution: 12bit (at 24V with maximum load resistance 500Ω) |

| Model | HD323 |

| Ambient operating temperature | -20~70℃ |

| Material | PP (polypropylene) |

| Protection Standard | Equivalent to IP65 (Equivalent to IP20 when lid is open) |

| External Dimensions | φ93x110mm |

| Wiring cable length | 10m |

| Weight | 350g |

| Mounting screw(Former JIS) | G2(PF2) |

*Use resin nuts, flanges, etc. for installation.

Do not use metal nuts or flanges. Doing so may cause measurement errors.

Sensor installation

Ultrasonic Level Meter Cautions for Sensor Installation

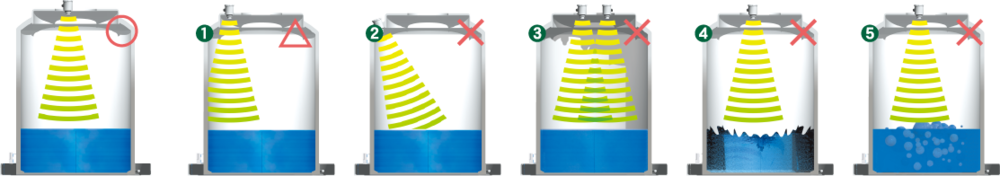

(1) Avoid obstacles

Install the ultrasonic level meter so that there are no obstacles within the sensor directivity angle.

Mask processing can be used for measurement.

(2) Install horizontally

Install the ultrasonic sensor so that its transmitting and receiving surfaces are horizontal to the object to be measured. Also, avoid installing the sensor in the center of the tank.

(3)Do not install multiple ultrasonic level meters in one same tank.

Installing multiple ultrasonic level meters in the same tank will result in mutual interference and inaccurate measurements.

(4)/(5)Avoid areas where waves or bubbles are generated.

If there are severe waves or bubbles on the liquid surface, measurement may not be possible.

*Use resin nuts or flanges for installation.

Do not use metal nuts or flanges. Doing so may cause measurement errors.